TIMING BELT AND TIMING CHAIN REPLACEMENT FREE GUIDE

FORD

HONDA

TOYOTA

VOLKSWAGEN

PEUGEOT

BMW

VOLVO

CHEVROLET

NISSAN

SUBARU

SUZUKI

MAZDA

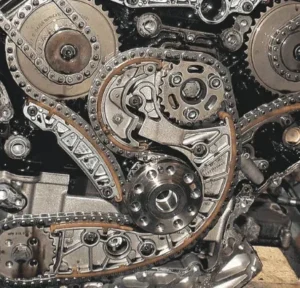

TIMING BELT AND TIMING CHAIN

Timing belts and timing chains are two different components used in internal combustion engines to synchronize the movement of the engine’s internal parts, specifically the rotation of the crankshaft and the camshaft. They play a crucial role in ensuring that the engine’s valves open and close at the right time in relation to the position of the pistons, which is essential for proper engine operation. Here’s a comparison of timing belts and timing chains:

Timing Belt:

- Material: Timing belts are typically made of rubber reinforced with fibers, such as fiberglass or Kevlar. They have teeth or cogs on their inner surface to engage with the pulleys.

- Maintenance: Timing belts require periodic replacement, and the replacement interval varies depending on the manufacturer and the specific engine. This is typically expressed in terms of mileage or time (e.g., every 60,000 miles or every 5 years).

- Tensioner: Timing belts are usually equipped with a tensioner and idler pulleys to maintain the correct tension and prevent slack.

- Noise: Timing belts tend to operate more quietly than timing chains because they are made of a quieter material.

- Cost: Timing belt replacement is a maintenance cost, and it can be relatively expensive due to the labor involved.

- Failure: If a timing belt breaks while the engine is running, it can lead to severe engine damage because the valves and pistons may collide.

Timing Chain:

- Material: Timing chains are made of metal, often alloy steel, and are designed with interlocking links that form a continuous chain. They do not have teeth like timing belts.

- Maintenance: Timing chains are designed to last the life of the engine in many cases and do not require regular replacement as long as they are properly maintained.

- Tensioner: Timing chains may also have a tensioner to maintain proper tension, but they are typically more robust and durable than timing belt tensioners.

- Noise: Timing chains can produce more noise during operation due to metal-to-metal contact, but this noise is often considered normal.

- Cost: Timing chain replacement is not a routine maintenance task and is generally less frequent than timing belt replacement, but it can be costly due to the complexity of the repair.

- Failure: Timing chains are less likely to break compared to timing belts. However, they can stretch over time, leading to timing issues and reduced engine performance if not properly maintained.

The choice between a timing belt and a timing chain largely depends on the manufacturer’s design and the specific engine model. Some engines use timing belts because they are quieter and less expensive to manufacture, while others use timing chains for their durability and longer lifespan. It’s important for vehicle owners to follow the manufacturer’s recommendations for maintenance to ensure the reliable operation of the engine. Additionally, if a vehicle has a timing belt, it’s crucial to replace it according to the recommended schedule to avoid potential engine damage in the event of a belt failure.

Timing belt and timing chain difference – Timing belt vs timing chain

Timing belts and timing chains are both crucial components in an internal combustion engine, and they serve the same fundamental purpose – synchronizing the rotation of the crankshaft and the camshaft. However, they have distinct differences in terms of construction, materials, and maintenance requirements. Here are the key differences between timing belts and timing chains:

Timing Belt:

- Material:

- Timing belts are typically made of rubber reinforced with high-tensile fibers like fiberglass or kevlar.

- Construction:

- They have a toothed design, resembling a belt with teeth on the inner surface.

- Noise:

- Generally quieter compared to timing chains in operation.

- Maintenance:

- Timing belts have a specific replacement interval, usually recommended by the vehicle manufacturer (e.g., every 60,000 to 100,000 miles).

- Failure to replace the timing belt within the recommended interval can lead to catastrophic engine damage if the belt breaks.

- Tensioners:

- Timing belts often use tensioners to maintain proper tension, preventing slack in the belt.

- Cost:

- Generally, timing belt replacement is less expensive than timing chain replacement.

Timing Chain:

- Material:

- Timing chains are usually made of metal and resemble a bicycle chain.

- Construction:

- They have a roller chain design, similar to a bicycle chain.

- Durability:

- Timing chains are known for their durability and are less prone to wear over time compared to timing belts.

- Noise:

- Timing chains can generate more noise during operation, especially as they wear. However, many modern engines have noise-reducing designs.

- Maintenance:

- Timing chains generally do not have a specified replacement interval.

- They are designed to last the life of the engine, but they can still experience wear over an extended period.

- Tensioners:

- Timing chains may have tensioners, but they are generally less prone to issues related to tension compared to timing belts.

- Cost:

- Timing chain replacement is often more expensive than timing belt replacement due to the labor-intensive process of accessing and replacing the chain.

Selection in Vehicles:

- Timing Belts: Commonly found in many smaller and mid-sized engines, especially in vehicles where cost and weight are significant factors.

- Timing Chains: Often used in larger engines, high-performance engines, and many modern vehicles where durability and longer maintenance intervals are emphasized.

It’s essential to follow the manufacturer’s recommendations regarding maintenance and replacement intervals for timing belts or chains to ensure the proper functioning and longevity of the engine.

Timing belt to timing chain conversion

Converting a timing belt system to a timing chain system, or vice versa, is a complex and challenging task that involves significant modifications to the engine. It’s important to note that such a conversion is not a common or straightforward procedure, and it is not recommended for the average vehicle owner. Here are several reasons why:

- Engine Design:

- The choice between a timing belt and a timing chain is typically made during the initial design and engineering of the engine. Converting from one system to another would require extensive modifications to the engine’s design, including changes to the engine block, cylinder head, and other critical components.

- Space Constraints:

- The engine bay is designed to accommodate the specific timing system used in the original design. Changing the timing system may require altering the physical dimensions of the engine, which could be impractical or impossible due to space constraints.

- Engine Management System:

- The engine’s electronic control unit (ECU) is calibrated to work with the specific timing system. Switching from a timing belt to a timing chain or vice versa would likely necessitate reprogramming or replacing the ECU to ensure proper engine performance.

- Crankshaft and Camshaft Compatibility:

- The conversion would require changes to the engine’s crankshaft and camshaft components to accommodate the new timing system. Achieving compatibility between these components is a significant engineering challenge.

- Accessory Components:

- Various accessory components, such as the water pump, tensioners, and pulleys, are designed to work in conjunction with the specific timing system. Converting to a different system would require modifications to these components.

- Cost and Expertise:

- Converting from a timing belt to a timing chain or vice versa is a labor-intensive and costly process. It would likely require the expertise of highly skilled automotive engineers and mechanics.

- Warranty and Reliability Concerns:

- Engine manufacturers design and test engines with a specific timing system for reliability and performance. Modifying the engine’s fundamental design may compromise its reliability and could void any existing warranties.

- Legal and Regulatory Compliance:

- In some regions, vehicle modifications may be subject to legal and regulatory requirements. Converting a timing system may lead to compliance issues and could affect the vehicle’s emissions and safety standards.

Due to the complexity and challenges involved, it’s generally not recommended to attempt a timing belt to timing chain conversion or vice versa. If you have concerns about your vehicle’s timing system, it’s advisable to follow the manufacturer’s maintenance recommendations and consult with qualified automotive professionals for guidance.

HOME